Control and Automation Inc (CAI) provides industrial machinery control programming and design services. Completed projects range from designing, assembling, and integrating “one of a kind” machines to prototyping, developing and manufacturing scale up for applications that have targeted install base of +/- 5,000 duplicate machines. Our experience includes legacy equipment (such as the Mitsubishi A-series motion controller, or the Allen Bradley PLC-5 and SLC 500) as well as the latest in control hardware and software.

Control & Automation, Inc.

The skill sets that CAI provides its customers are:

- Sequential machine control using control logic programming

- Fault reporting and recovery

- Data acquisition, reporting, and logging

- Operator Interfaces (touchscreens)

- Motion / Servo Control

- Upgrade / Conversion of obsolete hardware & software to current standards

- Recipe / Batch management systems

- Shop Floor Data Management and Control Networks

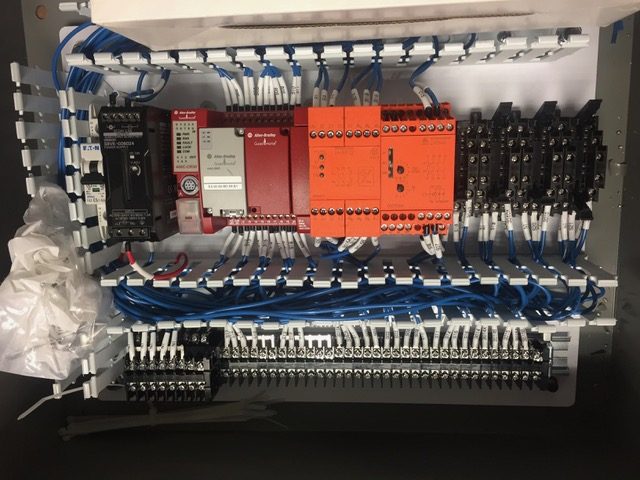

- Electrical Schematics: Design and Development

- Control Panel: Design and Build

- Operator safety and protection considerations, TUV Factory Safety Certified Staff

- Mechanical Design services that complement and work with control system to provide a “turn-key” package for customers / end users.

Specific applications are detailed in the gallery of completed projects. These include systems for automotive component and sub-assembly manufacturing, food and consumer good and other manufacturing applications. Completed projects range from the simple conveyor photo-eye and motor control systems to complex machines with 16+ axis of servo motion control with data logging / reporting and interfaces to higher level data management systems.

Contact us to tell us more about your application and how CAI can deliver the automation solutions you need.