RFID And Data Handling Upgrade

The issue to work around was the specific hardware constraint of the Mitsubishi A series only being able to have…

Control and Automation Inc (CAI) provides industrial machinery control programming and design services. Completed projects range from designing, assembling, and integrating “one of a kind” machines to prototyping, developing and manufacturing scale up for applications that have targeted install base of +/- 5,000 duplicate machines.

Our experience includes legacy equipment (such as the Mitsubishi A-series motion controller, or the Allen Bradley PLC-5 and SLC 500) as well as the latest in control hardware and software.

Specific applications are detailed in the gallery of completed projects below. These include systems for automotive component and sub-assembly manufacturing, food and consumer good and other manufacturing applications. Completed projects range from the simple conveyor photo-eye and motor control systems to complex machines with 16+ axis of servo motion control with data logging / reporting and interfaces to higher level data management systems.

Completed projects range from designing, assembling, and integrating “one of a kind” machines to prototyping, developing and manufacturing scale up for applications that have targeted install base of +/- 5,000 duplicate machines.

The issue to work around was the specific hardware constraint of the Mitsubishi A series only being able to have…

New Machine guarding was implemented after a risk and hazard assessment. Control panel was mounted directly to the machine base,…

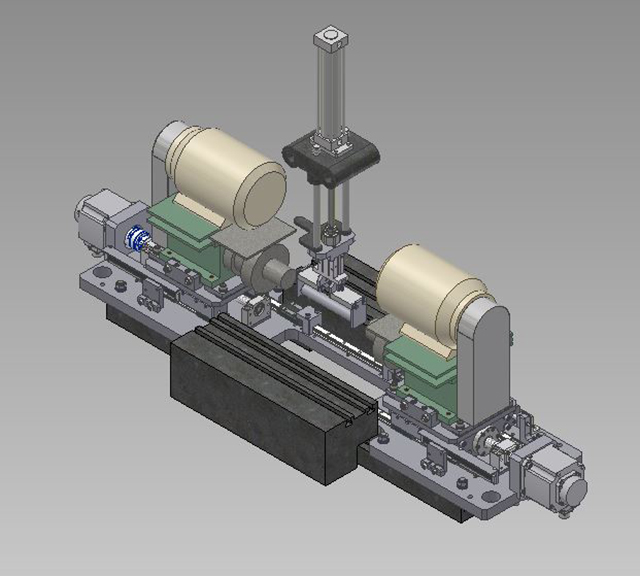

Customer needs this machine to verify manufacturing process changes, functionally test sample materials and endurance test parts for customer quality…

– Big Rapids Products, Mt. Sterling KY. CAI scope of work was ladder logic conversion, develop new screens for operator…

Upgraded the SLC-5/03 processors to CompactLogix (1769-L33ER) with 1769 I-O. Moved touchscreen functions to Factory Talk PanelView 7 Enhanced. All…